The challenges in manufacturing

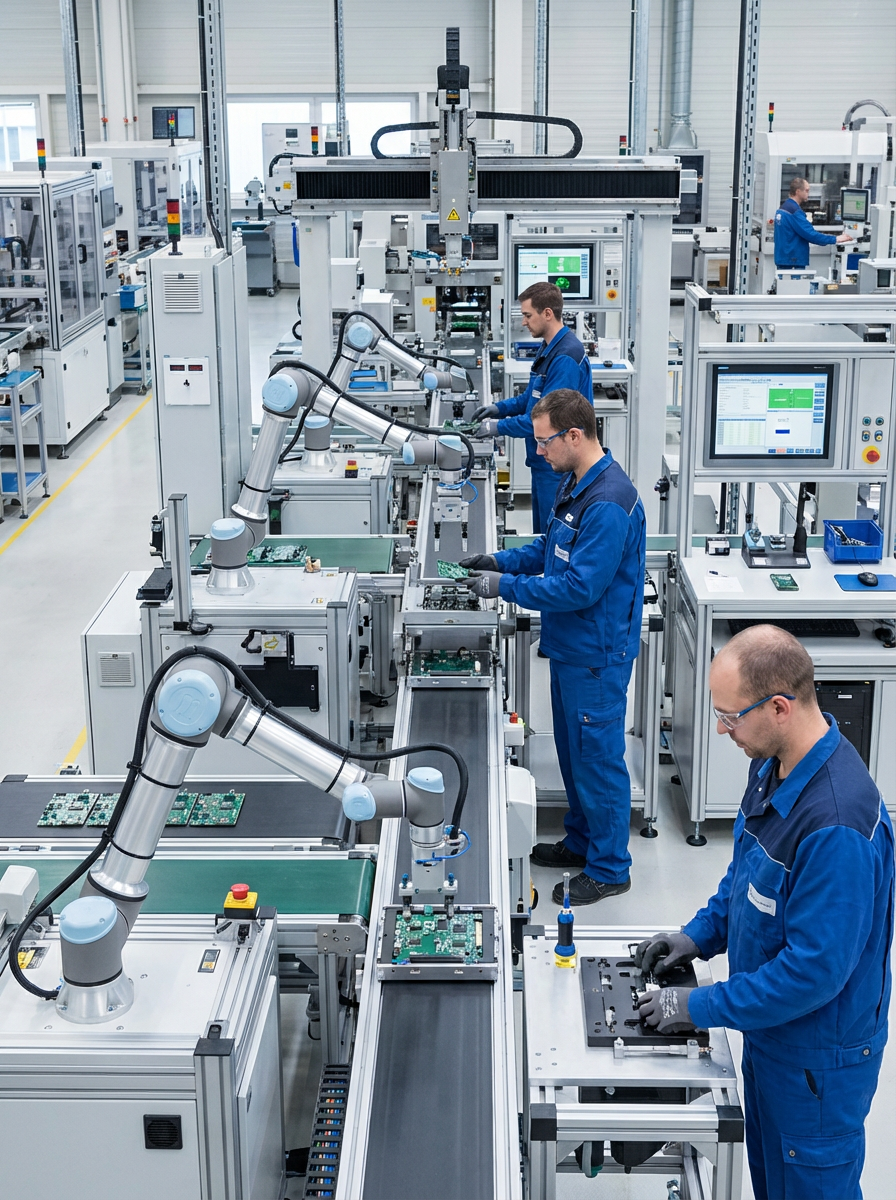

In manufacturing, everything changes last minute: order changes, setup times, machine failures, absences, quality issues, material shortages. SOLUTIO plans people, machines, and resources together and replans in seconds as soon as reality changes.

On the shop floor, “who-what-when” is never enough. You have to consider capacity, skills, shifts, machines, maintenance, material availability, and quality requirements, and all of that while the planning is continuously moving.

Do you recognize this?

The day starts with a plan… until a machine fails, an order shifts or an urgent production batch comes in between

Operators are available, but missing certification, line knowledge or safety certificates

Materials are scheduled, but delivery, inventory or internal logistics is lagging behind

Departments each plan in their own tool/Excel: versions clash and production 'improvises'.

Registrations come in afterwards with discussion: who did what, when, on which line and with what output/scrap

Machines are 'free', but maintenance, inspections, tools or changeover/setup time are not accounted for

With static planning, you get stress, hidden waiting times, and last-minute fires. SOLUTIO makes planning dynamic: constraints are automatically taken into account, and teams always work with one current plan.

They rely on SOLUTIO

The platform for modern industry and manufacturing companies

Shift planning &

team allocation

Plan shifts, lines, tasks, and staffing in one visual overview, real-time, without version chaos

Automatic

rescheduling

In case of machine failure, order changes, or absences, SOLUTIO recalculates a feasible plan in seconds

Competencies &

certificates

Automatically match the right operators based on skills, line authorizations, certifications, and safety requirements

Machines, tools &

maintenance

Plan machines, changeover times, tooling, inspections, and maintenance so that the line does not "stop due to details"

Work order &

floor registration

Operators register hours, output, scrap, breakdowns, photos, and checklists directly at the line

Reporting &

ERP-ready follow-up

Approved performance and production data flow into reporting and post-calculation/ERP

Always the right people and resources in the right place

SOLUTIO calculates (automatically) with among others:

Availabilities (shifts, schedules, absences, deployability)

Competencies & certificates (line knowledge, safety, certifications)

Machine availability (status, maintenance, inspections, tooling)

Changeover times & dependencies (product changes, batch logic, sequences)

Material availability (inventory, deliveries, internal logistics)

Capacity/productivity per line, team, or product type

- Less planning stress for production and team management

- Less ad-hoc "puzzle work" and "line-stop surprises"

- Faster response to downtime, urgent orders, or order changes

- More peace: everyone works with the same current plan

Digital work orders & registration on the shop floor

Teams can easily register via the mobile app:

Start/stop, breaks, attendance (per line/task/order)

Output, scrap, deviations, quality checks

Downtime, comments, photos, and attachments

Checklists (safety, quality, startup/reconfiguration)

Documents per order (work instructions, procedures, certificates)

This makes usable data a reality on the shop floor immediately for follow-up, post-calculation and correct processing, without wrong interpretations afterwards.

Closing

without discussion

Approved performances automatically go to the back office.

- Approved hours and performances are ready for processing in ERP

- Fewer manual corrections, less “why doesn’t this match?”

- Faster closing due to consistent data

- Payroll-ready via VIRO: allowances/rules automatically according to internal agreements and sector regulations

Result

- Fewer errors

- Less interpretation

- Faster closing

- More control for production & back office

The platform for modern industry and manufacturing companies

100%

real-time insight

Rescheduling

in seconds

Ideal for shifts

& multi-site

Machines + people

+ resources in one flow

Samsonite – A success story

Turning Excel chaos into order: Samsonite’s smart planning success.

Challenge:

Samsonite’s European distribution center in Oudenaarde used to manage staff planning entirely in Excel—leading to errors, wasted time, and frustrated teams. Multiple warehouses, complex shifts, and temporary workers made planning nearly impossible.

Solution:

With SOLUTIO from GO-VIRTUAL, all staff planning was digitized. The system accounts for skills, availability, and rotation preferences while connecting directly to HR and time-tracking systems. Automatic rotations, real-time data, and transparent planning now give Samsonite a complete overview with minimal errors.

Read the full case

Source: Value Chain Management (oktober–november 2025)